Learn about concentric butterfly valve

Concentric butterfly valves are a type of valve commonly used in various industries to regulate the flow of fluids in pipelines and other equipment. Their simple design, low cost, and ease of operation make them a popular choice for applications where quick and efficient control of fluid flow is required. In this article, we will explore the structure, operation, advantages, disadvantages, and applications of concentric butterfly valves, providing you with a comprehensive understanding of this important valve type. Whether you are a professional in the industry or simply curious about the inner workings of valves, read on to learn more about concentric butterfly valves.

What is a concentric butterfly valve?

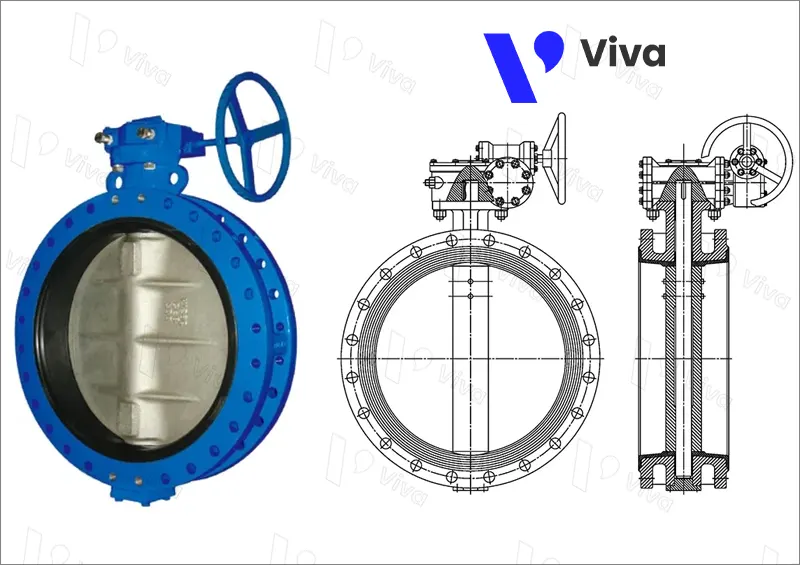

A concentric butterfly valve is a type of valve that controls the flow of a fluid (gas or liquid) through a pipe. It consists of a circular disc, which is mounted on a shaft, and is positioned in the center of the pipe. The disc rotates around the shaft to open or close the valve.

When the butterfly valve is fully open, the disc is parallel to the direction of flow, allowing the fluid to pass through with minimal resistance. When the valve is closed, the disc is perpendicular to the direction of flow, blocking the flow completely.

The term “concentric” refers to the fact that the disc is positioned at the center of the pipe, with the shaft passing through the center of the disc. This design results in a uniform seal around the entire circumference of the valve, which provides reliable sealing and prevents leakage.

Concentric butterfly valves are commonly used in a variety of industrial applications, including water treatment, HVAC systems, and food processing. They are often preferred over other types of valves due to their simple design, ease of operation, and low cost.

Structure of concentric butterfly valve

A concentric butterfly valve consists of several main components that work together to regulate the flow of fluids through a pipeline.

The main components of a concentric butterfly valve include:

- Body: The body of the valve is typically made of cast iron, ductile iron, or stainless steel. It is designed to be durable and to withstand high pressures and temperatures.

- Disc: The disc of the valve is circular in shape and is attached to a shaft that passes through the center of the valve. The disc is responsible for controlling the flow of fluid through the valve.

- Shaft: The shaft of the valve is usually made of stainless steel and is responsible for rotating the disc to open or close the valve.

- Seat: The seat of the valve is a flexible seal that is attached to the body of the valve and provides a tight seal around the disc to prevent leakage of fluid.

- Stem: The stem of the valve is a rod that connects the shaft to the handle or actuator, which is used to control the opening and closing of the valve.

- Handle or Actuator: The handle or actuator is used to rotate the stem and open or close the valve.

The structure of a concentric butterfly valve is designed to be simple and efficient, allowing for quick and easy operation. When the valve is open, the disc rotates to align with the flow of fluid, allowing for maximum flow. When the valve is closed, the disc rotates perpendicular to the flow of fluid, providing a tight seal to prevent leakage. The concentric design ensures that the valve provides a uniform seal around the entire circumference, ensuring reliability and preventing leaks.

Concentric butterfly valve operation

The operation of a concentric butterfly valve is relatively simple. When the valve is in the fully open position, the disc is positioned parallel to the flow of fluid, allowing maximum flow. When the valve is in the fully closed position, the disc is rotated perpendicular to the flow of fluid, preventing any flow.

To operate the valve, the handle or actuator is turned, which rotates the stem and shaft, causing the disc to rotate as well. As the disc rotates, it either opens or closes the valve, regulating the flow of fluid through the pipeline. The seat of the valve provides a tight seal around the disc, preventing any leakage of fluid.

One of the advantages of a concentric butterfly valve is its ability to provide a reliable seal with a low torque requirement. The concentric design of the valve ensures that the disc is always centered in the flow path, which reduces the amount of force required to operate the valve.

Concentric butterfly valves are commonly used in applications where quick and efficient regulation of fluid flow is required. They are often preferred over other types of valves because of their simple design, low cost, and ease of operation. However, they may not be suitable for applications that require precise flow control or where high pressures or temperatures are involved.

Advantages – disadvantages of concentric butterfly valve

Advantages

- Low cost: Concentric butterfly valves are relatively low cost compared to other types of valves, making them an economical option for regulating fluid flow.

- Simple design: The design of the concentric butterfly valve is simple, with few components, making it easy to install, operate, and maintain.

- Quick operation: Concentric butterfly valves can be quickly opened or closed to regulate fluid flow, making them ideal for applications where rapid control is necessary.

- Reliable sealing: The concentric design of the valve provides a uniform seal around the entire circumference, ensuring reliable sealing and preventing leakage.

- Low torque requirement: The concentric design of the valve reduces the torque requirement, making it easier to operate the valve.

Disadvantages

- Limited precision: Concentric butterfly valves may not provide the same level of precision as other types of valves, making them unsuitable for applications that require precise flow control.

- Limited temperature and pressure range: Concentric butterfly valves may not be suitable for applications that involve high temperatures or pressures, as the valve components may not be able to withstand these conditions.

- Limited chemical compatibility: The materials used to construct the valve may not be compatible with certain chemicals or corrosive substances, limiting their use in certain applications.

- Limited flow capacity: Concentric butterfly valves may have limited flow capacity compared to other types of valves, which may be a limiting factor in certain applications.

Overall, the advantages of a concentric butterfly valve include its low cost, simple design, quick operation, reliable sealing, and low torque requirement. However, its disadvantages include limited precision, limited temperature and pressure range, limited chemical compatibility, and limited flow capacity.

Application of concentric butterfly valve

Concentric butterfly valves are commonly used in a wide range of applications where rapid and efficient regulation of fluid flow is required. Some of the most common applications of concentric butterfly valves include:

- HVAC systems: Concentric butterfly valves are often used in heating, ventilation, and air conditioning (HVAC) systems to control the flow of air and water.

- Water treatment: Concentric butterfly valves are commonly used in water treatment plants to regulate the flow of water in various stages of the treatment process.

- Chemical processing: Concentric butterfly valves are often used in chemical processing plants to regulate the flow of chemicals and other fluids in various stages of the production process.

- Food and beverage processing: Concentric butterfly valves are used in food and beverage processing plants to regulate the flow of liquids and gases in various stages of the production process.

- Pharmaceutical manufacturing: Concentric butterfly valves are used in pharmaceutical manufacturing to regulate the flow of fluids and gases in various stages of the production process.

- Oil and gas: Concentric butterfly valves are used in the oil and gas industry to regulate the flow of fluids in pipelines and other equipment.

- Fire protection: Concentric butterfly valves are used in fire protection systems to control the flow of water in sprinkler systems and other firefighting equipment.

The versatility and efficiency of concentric butterfly valves make them a popular choice for a wide range of applications where quick and reliable regulation of fluid flow is necessary.

Types of concentric butterfly valves

Concentric butterfly valves come in different types to suit different applications and requirements. Here are some of the most common types of concentric butterfly valves:

- Wafer butterfly valves: Wafer butterfly valves are designed to be mounted between two flanges and are commonly used in HVAC, water treatment, and other applications where space is limited.

- Lug butterfly valves: Lug butterfly valves are similar to wafer butterfly valves but have threaded inserts on each side for easy installation and removal.

- High-performance butterfly valves: High-performance butterfly valves are designed to withstand high pressures, temperatures, and corrosive environments. They are commonly used in the chemical, petrochemical, and oil and gas industries.

- Cryogenic butterfly valves: Cryogenic butterfly valves are designed to withstand extremely low temperatures and are used in applications where cryogenic fluids are transported, such as in the medical, pharmaceutical, and food industries.

Understanding the different types of concentric butterfly valves can help professionals choose the right valve for their specific application and ensure optimal performance and efficiency.

Some famous brands of concentric butterfly valve production

There are several well-known manufacturers that produce high-quality concentric butterfly valves for various industries. Here are some of the most famous brands:

- Bray Controls: Bray Controls is a global manufacturer of industrial valves, including a range of butterfly valves, including concentric butterfly valves.

- Keystone: Keystone is a brand of Tyco Flow Control, which produces a variety of valves, including concentric butterfly valves, for various industries.

- DeZURIK: DeZURIK is a leading manufacturer of valves for water treatment, HVAC, pulp and paper, and other industries, including a range of concentric butterfly valves.

- Jamesbury: Jamesbury, a brand of Metso Corporation, produces a wide range of valves, including concentric butterfly valves, for various industrial applications.

- Val-Matic: Val-Matic is a leading manufacturer of valves for the water and wastewater industry, including concentric butterfly valves.

- Flowserve: Flowserve produces a wide range of valves for the oil and gas, chemical, and other industries, including high-performance concentric butterfly valves.

- Belimo: Belimo produces a range of valves and actuators for the HVAC industry, including concentric butterfly valves.

These are just a few of the many brands that produce concentric butterfly valves. When selecting a valve for a particular application, it is important to consider factors such as the pressure and temperature requirements, flow rate, and compatibility with the fluid being transported.

Summary of the article

Concentric butterfly valves are a popular type of valve used in various industries to regulate the flow of fluids in pipelines and other equipment. This article provides an overview of the structure, operation, advantages, disadvantages, and applications of concentric butterfly valves. The article also lists some of the most famous brands of concentric butterfly valve production, such as Bray Controls, Keystone, DeZURIK, and Jamesbury. Understanding the basic principles of concentric butterfly valves can help professionals in various industries make informed decisions about selecting the right valve for their specific application.